Table of Contents

The creation of modern stainless steel sculptures is a systematic and intricate process that involves multiple stages, from the initial concept to the final installation and ongoing maintenance. This article outlines each step in this process, providing insights into the craftsmanship behind modern stainless steel sculptures.

1. Define the Product Style

The first step in crafting a stainless steel sculpture is to establish the product style. This involves in-depth discussions between the artist and the client or design team to determine the sculpture’s theme, style, and purpose. During this phase, sketches and preliminary concepts are exchanged to ensure that the final piece aligns with expectations.

2. Develop the 3D Design

Once the product style is confirmed, the next step is to create a detailed 3D design. Our designers utilize computer-aided design (CAD) software to transform the concept into a three-dimensional model. This model not only illustrates the shape and structure of the sculpture but can also be modified and refined to ensure technical feasibility and aesthetic appeal. At Alisn, our professional design team collaborates closely with clients to realize their vision, providing a clear preview of the final product.

3. Mold Creation

After finalizing the 3D design, the next critical step is mold making. The molds are essential for shaping the materials used in the sculpture. Alisn’s skilled workers create precise molds based on the design specifications, ensuring that each component’s size and shape meet the required standards. This stage is vital for maintaining the sculpture’s quality.

4. Material Cutting

Once the molds are ready, the next phase involves cutting the materials according to the design and mold specifications. High-precision tools, such as laser cutters or water jets, are employed to ensure accurate cuts for each component. The quality of this cutting process directly influences the subsequent assembly and welding stages, which is why Alisn’s craftsmen adhere to strict operational protocols at this stage.

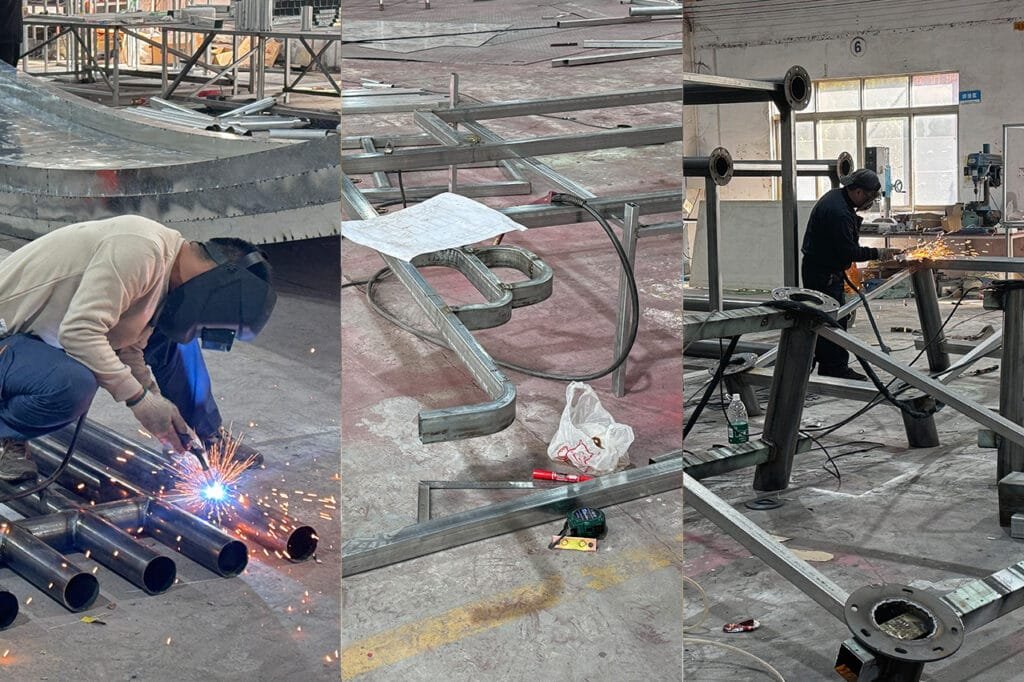

5. Forging and Welding

Following the cutting process, we move on to forging and welding. Craftsmen shape and join the cut parts during this stage. Forging typically involves heating and shaping the materials, while welding fuses the different components together at high temperatures. Common welding methods include TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. Maintaining high temperatures and precise control is crucial to ensure the strength and aesthetic quality of the joints.

6. Surface Treatment

After welding, the sculpture undergoes surface treatment. This process not only enhances the sculpture’s appearance but also significantly affects its durability. Common surface treatment techniques include polishing, spraying, and sandblasting. These treatments provide the sculpture with a glossy finish and texture while improving its resistance to environmental factors.

7. Installation

Once the sculpture is completed, it is transported to the installation site. During installation, workers select the appropriate methods based on the sculpture’s size and weight to ensure stability and safety. Proper installation is critical, as it influences both the visual impact of the sculpture and the safety of visitors.

8. Maintenance

Finally, maintenance is essential for preserving the sculpture’s beauty and functionality over time. Alisn’s maintenance team offers professional guidance on cleaning and inspection, addressing any potential rust or damage. Regular maintenance can extend the sculpture’s lifespan, allowing it to grace public spaces for years to come.

The production of modern stainless steel sculptures is a meticulous and systematic endeavor that requires the expertise and skills of both artists and craftsmen. Through this comprehensive process, sculpture manufacturers can create works that are not only visually striking but also artistically significant, providing profound experiences and emotions for viewers.