Table of Contents

- Preliminary Communication and Requirement Comprehension

- Budget Management

- Design and Planning Phase

- Model Creation and Client Approval

- Formal Production and Sculpture Formation

- Post – Processing, Decoration, and Installation

- Leave a Reply Cancel reply

Alisn, a seasoned sculpture brand supplier with 15 years of manufacturing expertise, recognizes that each sculpture in a large – scale project is not merely an artistic creation but also a crucial representation of corporate identity and project quality. To facilitate clients at all levels in understanding the entire custom sculpture process, we will provide a detailed introduction, starting from the overall framework down to each key step.

1. Preliminary Communication and Requirement Comprehension

Goal and Style Deliberation

Prior to project commencement, we initiate in – depth discussions with clients to clearly define the project’s positioning, the intended use of the product, the desired design style, and the budgetary range. For large – scale engineering projects, it is of utmost importance to establish the overall plan and safety parameters. This initial step serves as the foundation for the entire process. Only by having a clear understanding of your expectations can we ensure precise control in subsequent stages.

Project Site Layout and Data Gathering

Based on the specific requirements of different projects, we may engage in discussions regarding the on – site layout and collect essential information such as the surrounding environment, dimensions, etc. This ensures that the design and subsequent installation processes meet the project’s practical needs while strictly adhering to relevant safety regulations.

2. Budget Management

Comprehensive Budget Planning

Following the preliminary communication, we formulate a detailed budget plan tailored to the project’s overall requirements and scale. Clients of large – scale projects typically place significant emphasis on cost control. We allocate budgets meticulously at the outset, covering all aspects including design, production, installation, and post – maintenance, to guarantee the smooth execution of the project within the budgetary constraints.

Risk and Contingency Planning

During the budget planning process, we take into account all potential variables that may arise during the project. We set aside contingency funds and develop risk management strategies. This not only ensures that the project costs remain manageable but also provides multiple safeguards for project safety, thereby creating a robust financial and safety barrier for our clients.

3. Design and Planning Phase

Product Design Plan Development

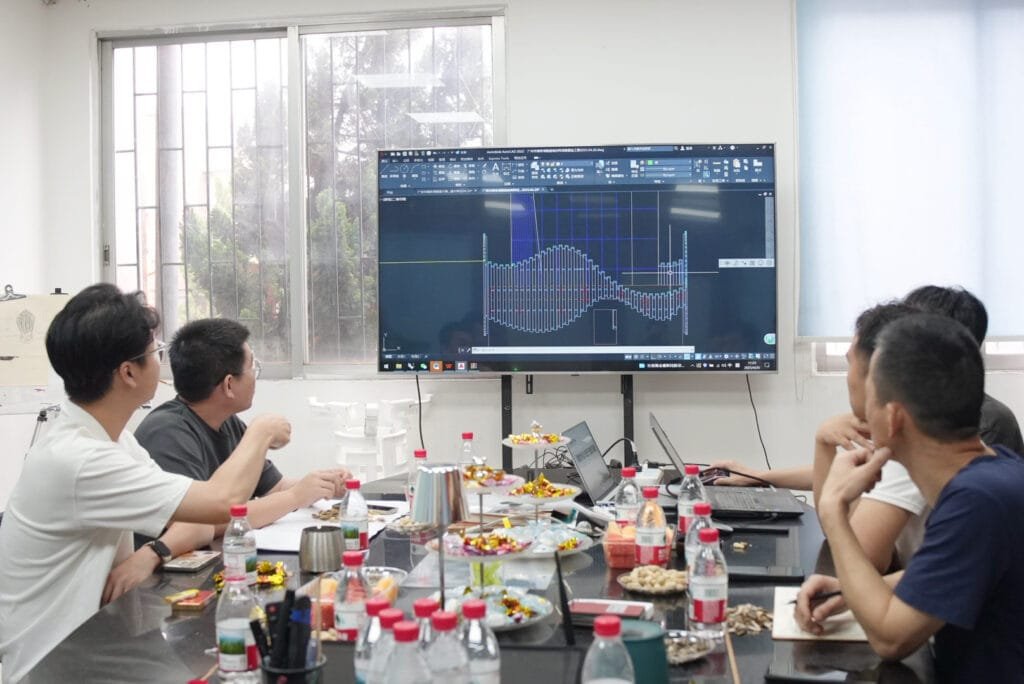

Building on the foundation of thorough communication, our professional design team formulates a practical product design plan in accordance with client requirements. We leverage advanced CAD technology to rapidly transform design concepts into detailed blueprints, ensuring that every aspect can be accurately implemented. For large – scale projects, we pay particular attention to the design’s functionality and safety, aiming to strike the perfect balance between artistic expression and project feasibility.

Detailed Scheduling and Budget Control

After several rounds of discussions and plan refinements, we create a detailed production schedule, encompassing time management, material selection, budget allocation, and safety protocols. Project budget and risk control are of prime concern to large – scale engineering clients. We exercise strict control over every aspect to ensure that the project progresses efficiently and safely within the budget.

Alisn boasts its own in – house professional design team. This team is not only capable of translating clients’ ideas into product designs but also excels in implementing refined management through the use of the CAD system. We carefully consider both cost – effectiveness and construction safety during the plan adjustment process, ensuring that the final design meets both the aesthetic requirements and the practical needs of the project.

4. Model Creation and Client Approval

Handmade or Digital Model

To offer you a more intuitive visualization of the final work, we typically begin by creating a small – scale or partial – detail model. This model serves as a three – dimensional representation of the design plan and is a crucial medium for communication and approval.

Client Feedback and Revision

Once the model is presented, we invite clients to share their valuable insights. Based on your feedback, we make the necessary adjustments until both parties are satisfied with the model’s outcome.

5. Formal Production and Sculpture Formation

Material Selection and Techniques

Upon finalizing the design, we select the most appropriate materials based on the characteristics of the work, such as stainless steel, bronze, resin, etc. With our extensive production experience, we have well – established solutions for material processing and manufacturing techniques, ensuring the work’s stability and artistic appeal.

On – site Production and Sculpture Shaping

In our professional factory, highly skilled artisans meticulously complete every detail of the sculpture according to the approved model. From carving and casting to post – polishing, each process is stringently monitored to ensure that every piece is a masterpiece.

Alisn operates its own production facility, and each craftsman has over a decade of sculpture – making experience. This guarantees that every product is flawlessly crafted, enhancing both the efficiency and precision of the production process while also endowing each work with unique details and textures. Through the strict quality control of our in – house factory, we are able to offer clients more reliable and high – quality customized services.

6. Post – Processing, Decoration, and Installation

Surface Treatment and Decoration

After the sculpture is completed, we perform surface treatment procedures such as polishing, spraying, or waxing to enhance its texture and protective properties. For large – scale projects, we may also add a protective coating or specialized decorations based on the on – site environment. This not only elevates the visual appeal but also improves the product’s weather resistance and safety.

Professional Installation and Project Safety Assurance

Once the sculpture is ready, we dispatch a professional installation team to carry out on – site construction. During the installation process, we strictly comply with safety standards and conduct multiple inspections of the equipment and installation site to ensure that the sculpture is securely and safely installed. Additionally, we offer after – sales maintenance services, conducting regular checks and upkeep to ensure the sculpture’s safety and maintain the project in optimal condition throughout its long – term use.

Throughout the entire custom sculpture journey, Alisn remains committed to the principles of professionalism, dedication, and meticulous care. From the initial requirement communication, budget management, product design, and CAD – based implementation, to model approval, meticulous production, and finally, safe installation and post – maintenance, we maintain strict control over every step. This ensures that both the project costs and safety are fully protected. Whether you are the planner or the executor of a large – scale engineering project, we are dedicated to helping you achieve unique sculpture artistry and project value through our professional and comprehensive services.